QUALITY STANDARDS

Maintaining Quality has always been the top most priority at Creatons. Our core team ensures that quality standards are practiced in everything we do, right from project initiation stage till the time it gets delivered safe and sound to our clients.

We conduct regular quality control meetings to analyze the current product quality issues and in-house quality concerns to identify underlying issues if any and brainstorm ways to improve the existing procedures and set the next level Quality Control Benchmarks. Our QC engineers are well-trained to follow the ISO and ESD standards in all of our manufacturing processes. They undergo continual advancements through regular in-house trainings on latest quality control standards, productivity enhancement measures and waste reduction techniques.

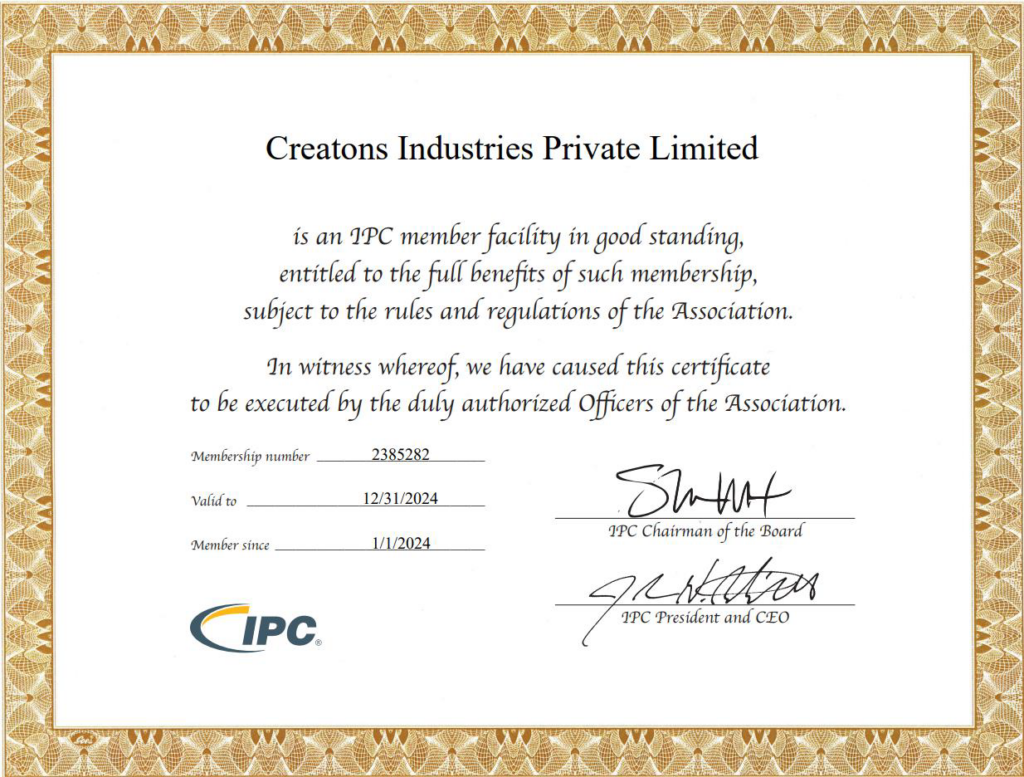

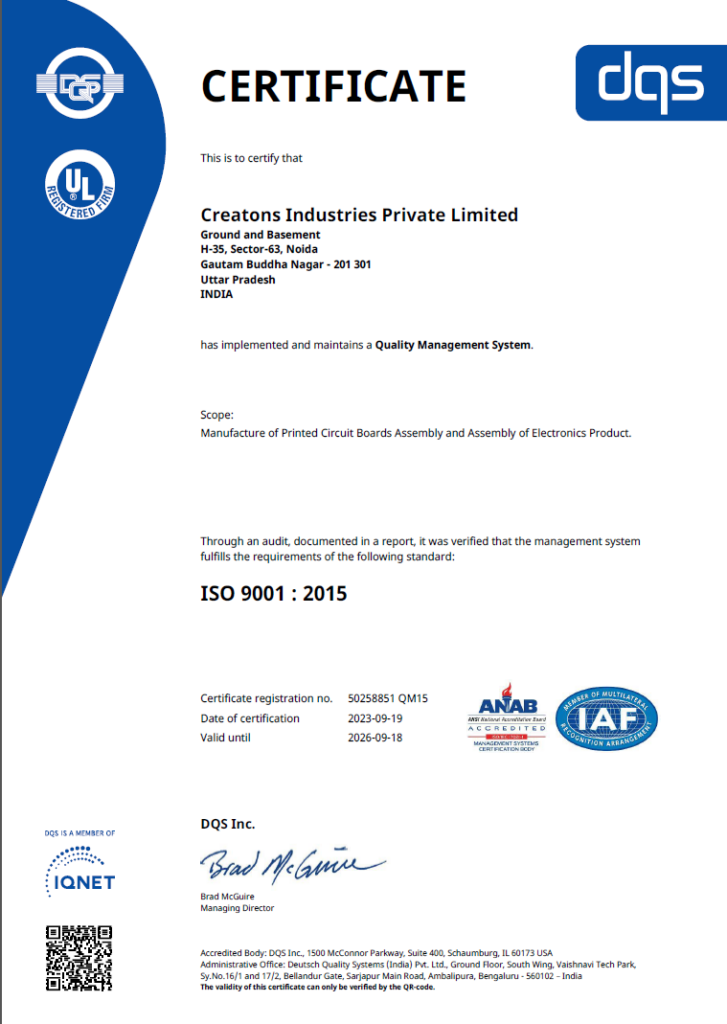

We follow the ISO 9001: 2015 standards to meet the requirements of a superior Quality Management System. Our team delivers products and services that consistently meets customer and necessary regulatory requirements.

At Creatons, we follow the framework detailed in ISO 14001 related to Environment Management to try and minimize the adverse affects that our processes could have on the environment and how to continually improve on them.

Safe and Healthy workforce ensures a happy workplace. We follow the guidelines of ISO 45001 to help minimize occupasional injuries and diseases, in addition to promoting and protecting physical and mental health.

Our engineers are trained in ESD Standards to help design, establish, implement, and maintain an Electrostatic Discharge Control program to protect electronic parts, assemblies and equipment which are susceptible to ESD damage.

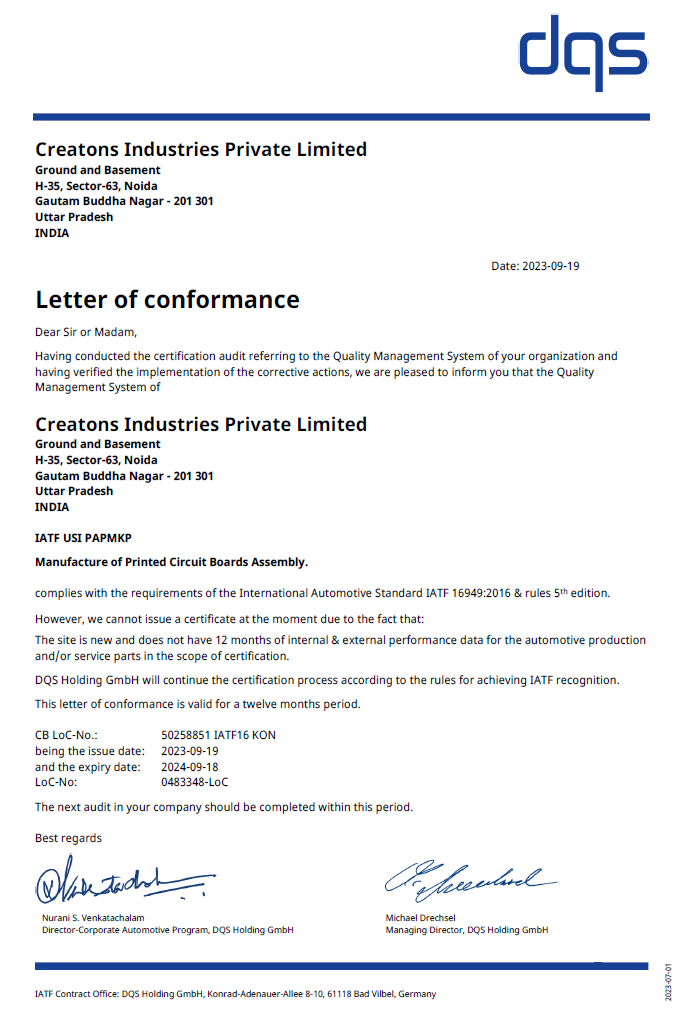

We follow the IATF 16949 : 2016 Automotive Industry QMS which provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the automotive industry supply chain and assembly process.

We implement and follow IPC standards at every stage of the electronics product development life cycle. This helps to ensure quality, consistency and reliability in our products.

FINEST QUALITY CONTROL PROCEDURES

Delivering products and services of best quality standards has been Creatons motto from the start. Creatons deploys well-trained, dedicated Quality Control Team, which makes sure that every product that is dispatched is the most reliable.

• Dedicated Quality Control Department

• 4-step In-House Quality Checks (QCs)

• Quarterly meetings to review the Quality Procedures for continuous improvement

• Quality check points at every level starting from store to production to packing to final dispatch.

WE BELIEVE IN EXCELLENT QUALITY – HAPPY CLIENTS – STRONGER BUSINESS RELATIONSHIPS!

NPI

Supplier Management

Material Management

Evaluation Plan

Performance Appraisal

IQC

Validity

Promptness

Pass Rate

Miss Rate

IPQC

Check List

7S / ESD / MSD

Inspection and Practice

FQC

Safety Performance

FPY

OQC

Packaging

Out-of-Box Non-Conformity Prevention

Adherence

Data Analysis

Monthly Meeting